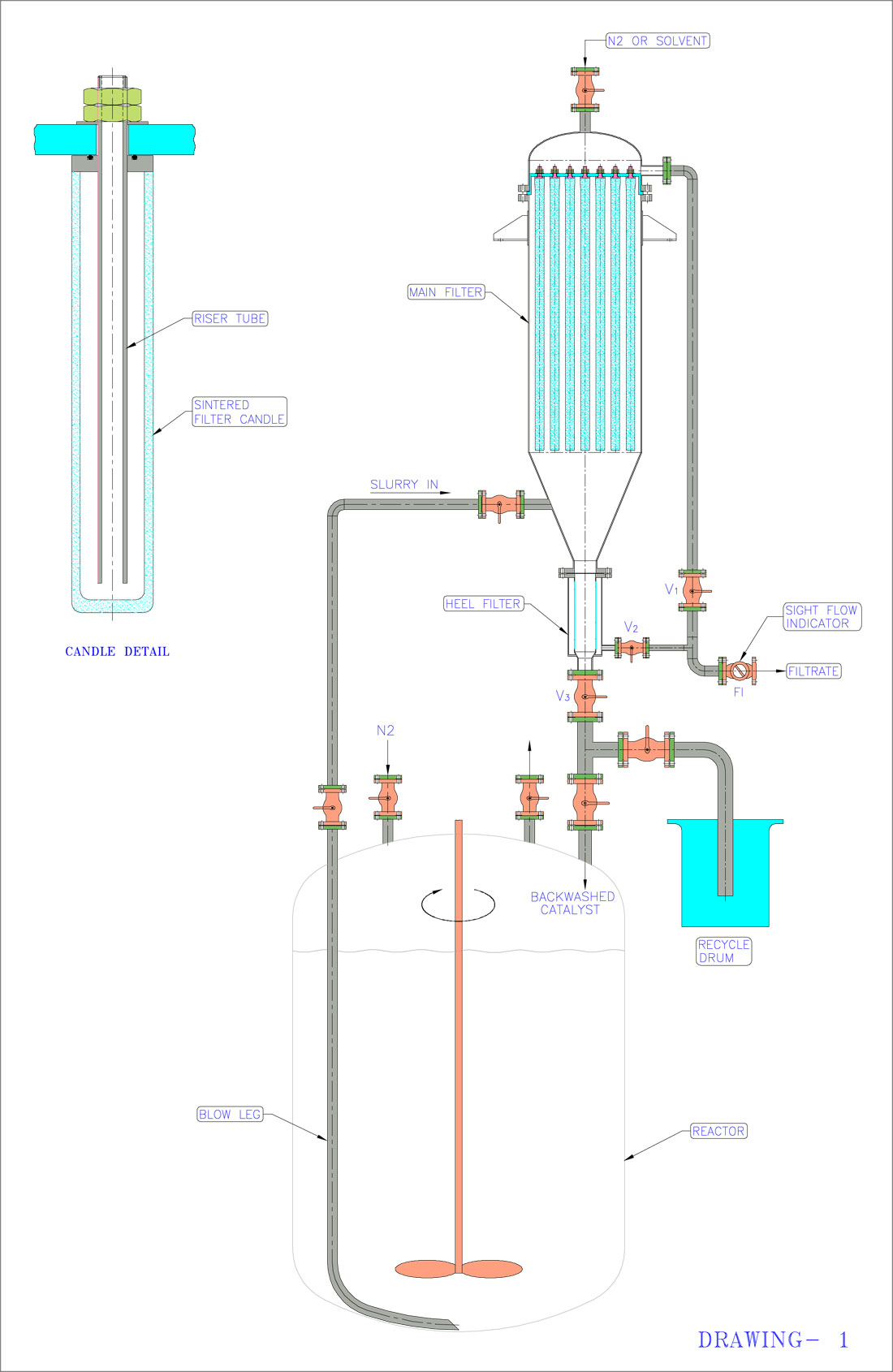

Operating principle and procedure

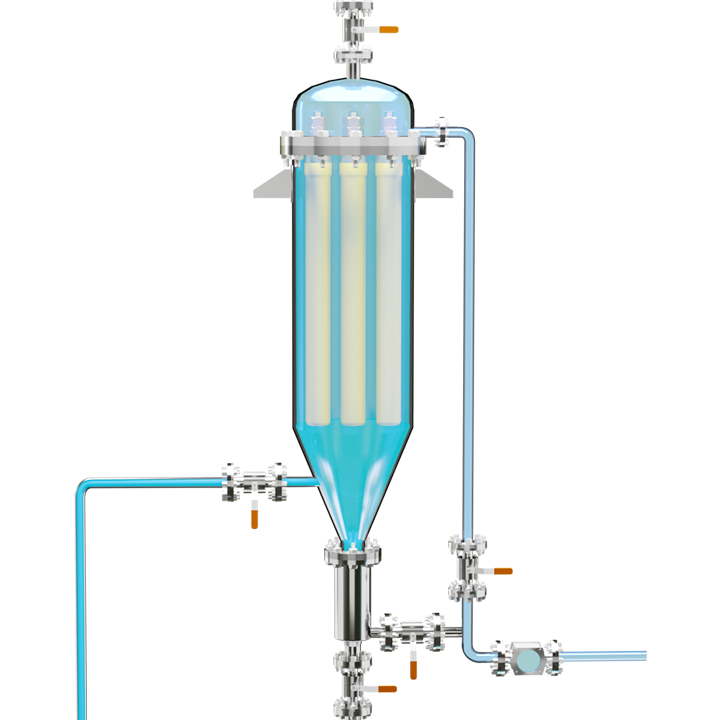

Catalyst filtration is an important aspect of a Hydrogenation system. Omega ‐ Kemix

supplies a cost effective system, which incorporates complete filtration, operational

safety, full backwash, as well as minimal holdup of the reaction mass

At the completion of hydrogenation reaction, balance Hydrogen gas in reactor

headspace is vented, and the Reactor is purged with Nitrogen, to eliminate all traces

of remaining Hydrogen. Subsequently, the Reactor is pressurized to about 1 bar with

Nitrogen, through Valve V1 Valves V2, V3 and V4 are opened. All othe valves (V5 to

V8) are in closed position. Nitrogen is continuously fed through Valve V1, so that

Reactor pressure is maintained around 1 bar.

Typically, if the catalyst is noble metal on a carrier, e.g., Pd/C, the entire mass is

filtered. In this case, it is advisable to stir the reaction mass at around 50 RPM, and

the dip pipe or blow leg should extend to the lowest possible point in the Reactor.

For heavy metal catalysts like Raney Nickel, the bulk of the catalyst settles within a

very short time, typically 30 minutes after cessation of stirring. In this case, a

common practice is to filter the supernatant liquid (through a dip pipe terminating

just below the lower tan line of the Reactor).

Nitrogen pressure in the Reactor headspace forces the liquid‐catalyst slurry into the

Main Filter through Valve V3. This filter is fitted with sintered SS 316 L candles,

suspended from a tubesheet.

Initially, the Filter body fills up with Liquid‐catalyst slurry. When it is full, filtration

commences. Catalyst cake accumulates outside the candles. Clear filtrate enters the

candles, and flows out through Valve V4. Filtrate flow can be observed through Sight

Flow Indicator (FI).

Once the Reactor contents are entirely displaced by Nitrogen, gas will flow into the

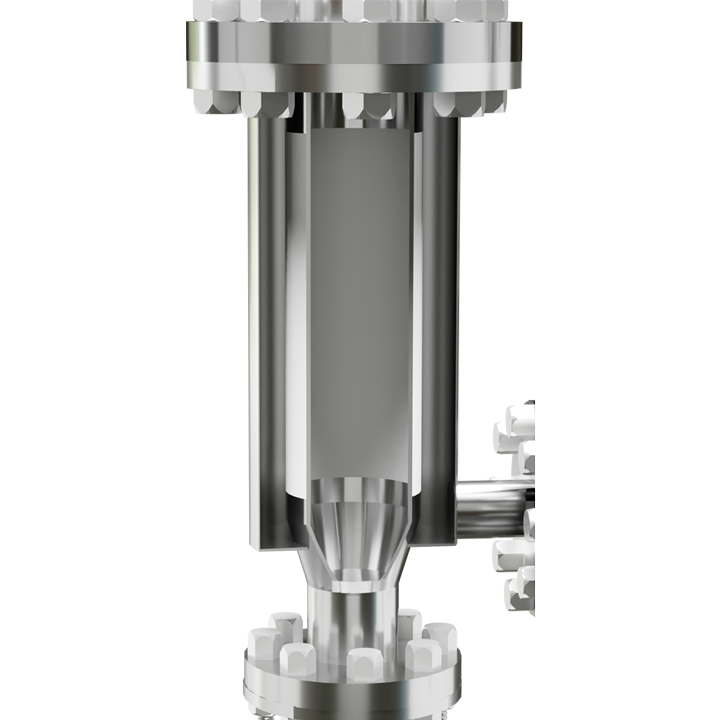

Filter through V3. The Filter Candles are fitted with an inner Siphon Tube. Gas

entering the Filter displaces the slurry, so that clear liquid is siphoned out through

Valve V4 due to action of siphon tubes in the candles. Due to this action, slurr level

in the Filter falls to the lower end of the candles. In effect, the filter cone and lower

parts are full of unfiltered slurry (also known as "Heel"), and candles are coated with

wet cake.

At this point, only gas flows through the Sight Flow Indicator

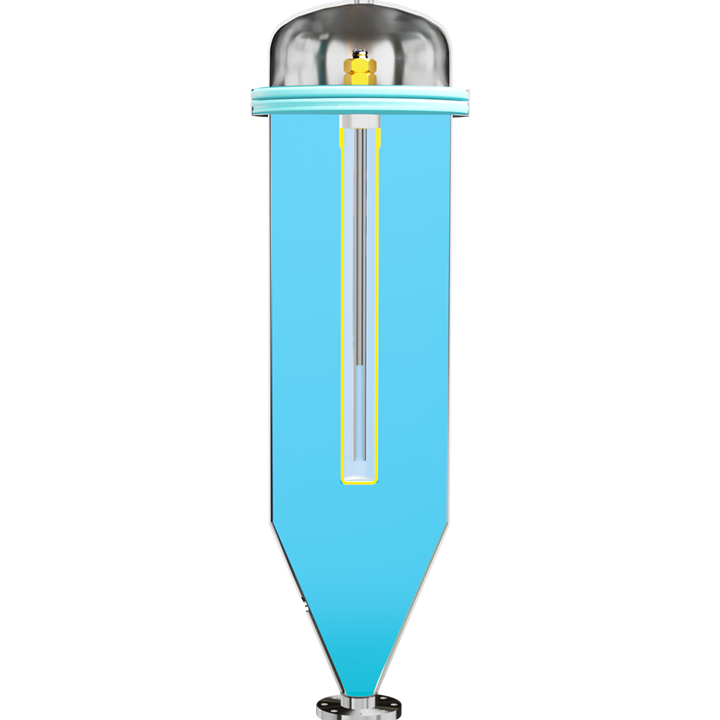

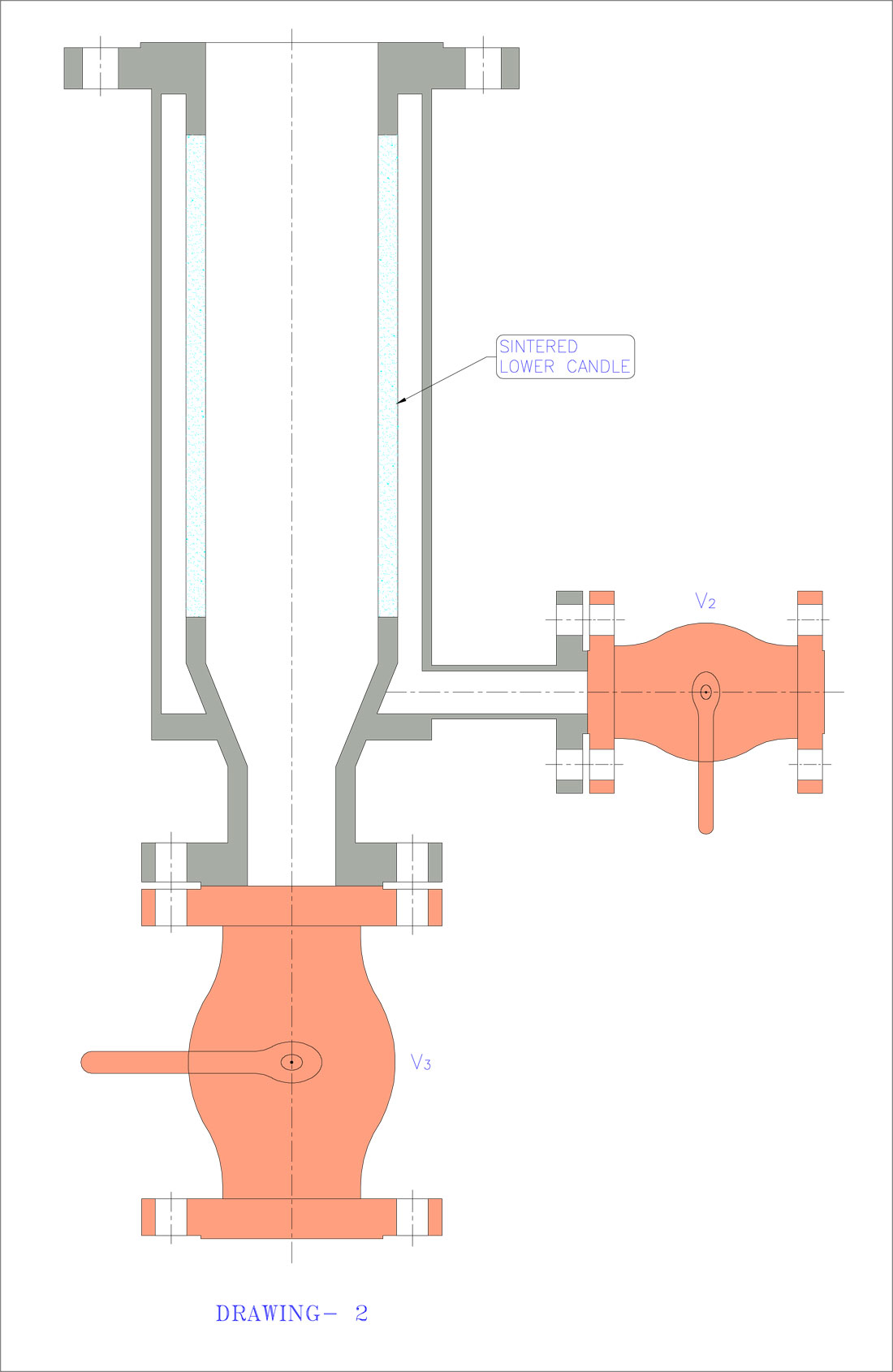

A Zero Holdup Filter is fitted at the lower end of the Main Filter, below the conical

portion. This is a Jacketed Sintered pipe (or Lower Candle), around 125 mm inside

diameter, suitable for inside to outside filtration. Please refer Drawing 2 for details of the Zero Holdup Filter.

When gas flow (i.e., no liquid flow) is observed through the Sight Flow indicator as

described above, Valve V4 is closed, and V9 is opened. Nitrogen gas entering the Filter

cone forces filtrate through the Lower Candle, so that slurry in the Filter Cone and

lower parts is filtered through the Zero Holdup Filter. Heel filtrate is observed flowing

through the Sight Flow Indicator FI.

Once the entire heel slurry is filtered, no further liquid flow is observed through the

Sight Flow Indicator. All the slurry has been filtered. At this stage, outer surfaces of

the upper candles, and inner surface of the lower candle are covered with wet cake.

Valves V9, V3 and V2 and V1 are now closed, and the Reacto vented to atmospheric

pressure, by opening Valve V10. Solvent/feed for the next batch, or Nitrogen at 1 to 5

bar is introduced at Valve V5, located at the top of the Filter. Keeping Valve V10 open,

Valve V8 and then Valve V6 is opened, so that catalyst adhering to candle surfaces

gets back‐flushed into the Reactor.

For best results, Valve V6 should be a Solenoid operated ball valve, so that there is a

pressure pulse while opening this valve. This ensures effective dislodgement of

catalyst cake from the Candles.

This procedure ensures a safe procedure for catalyst filtration from the Autoclave.

There is no spillage of expensive catalyst. The closed circuit operation avoids fire

hazards, as many catalysts are pyrophoric, and can spontaneously ignite when

exposed to air. High efficiency candles result in very low losses, which are often below

measurable limits. The filtration system pays for itself.

After several batch cycles, it may be necessary to remove catalyst from the system,

and send it for disposal or regeneration. In this case, Valve V7 is opened instead of V8,

during back flushing operation, and spent catalyst collected in the Recycle Drum.

Complete filtration

Complete filtration  Operational safety

Operational safety  Full backwash

Full backwash  Minimal holdup of the reaction mass

Minimal holdup of the reaction mass  Fitted with sintered candles

Fitted with sintered candles Has a special Heel filter

Has a special Heel filter  Provided with a sight flow indicator

Provided with a sight flow indicator  Provided with special valves for effective dislodgement of catalyst cake

Provided with special valves for effective dislodgement of catalyst cake