Several important chemical reactions are carried out in hazardous conditions. Examples of such reactions are as follows:

-

Pressure Reactions, such as Hydrogenation, Amination, etc.

Pressure Reactions, such as Hydrogenation, Amination, etc. -

Reactions with noxious gases.

Reactions with noxious gases. -

Manufacture of potent pharmaceuticals, such as hormones, oncology products, etc

Manufacture of potent pharmaceuticals, such as hormones, oncology products, etc -

Any other reactions requiring complete containment, and where there are zero leakage requirements.

Any other reactions requiring complete containment, and where there are zero leakage requirements.

In conventional reactors, the reaction mixture is agitated by an impeller connected to a rotating shaft. Necessarily, the shaft "punctures" the Reactor.

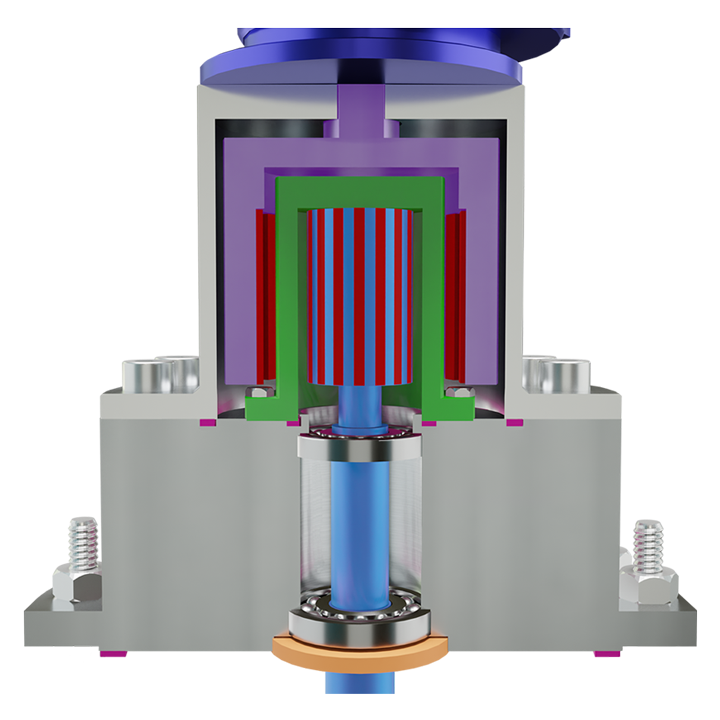

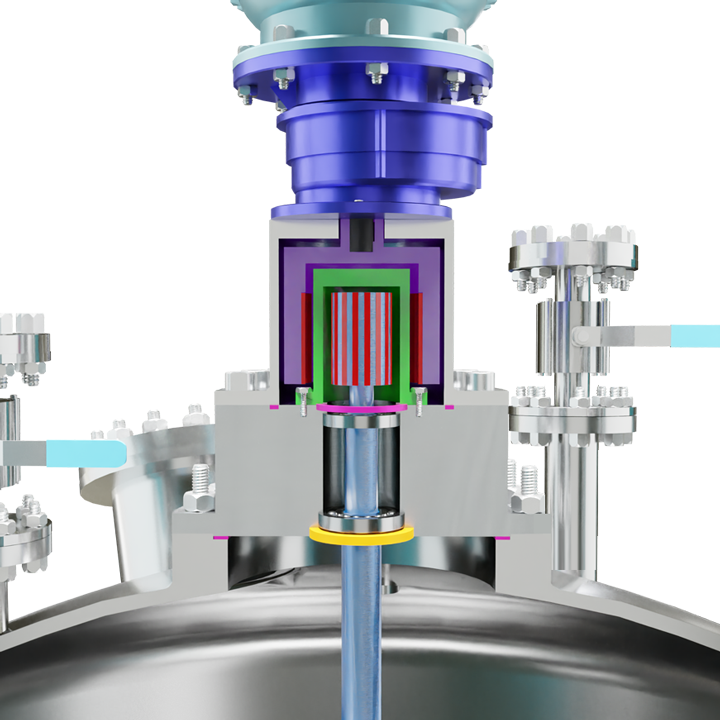

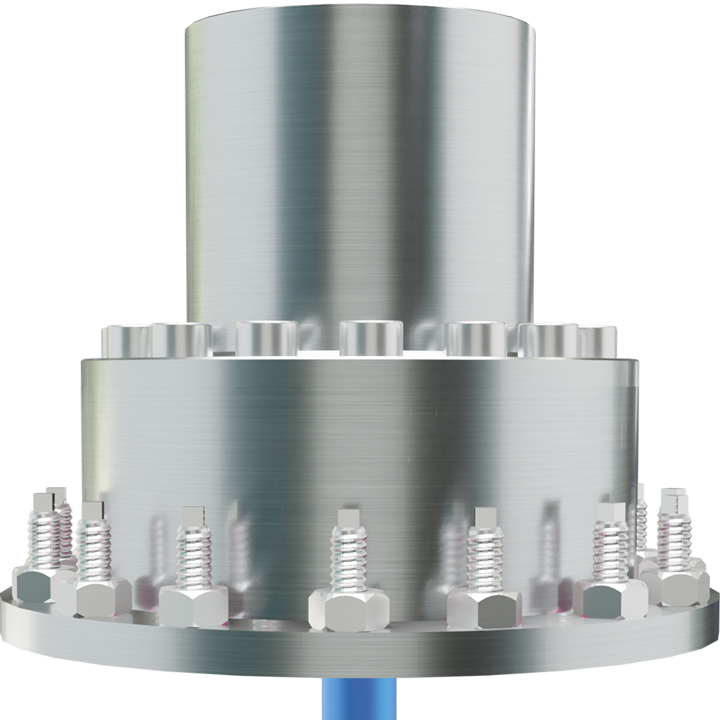

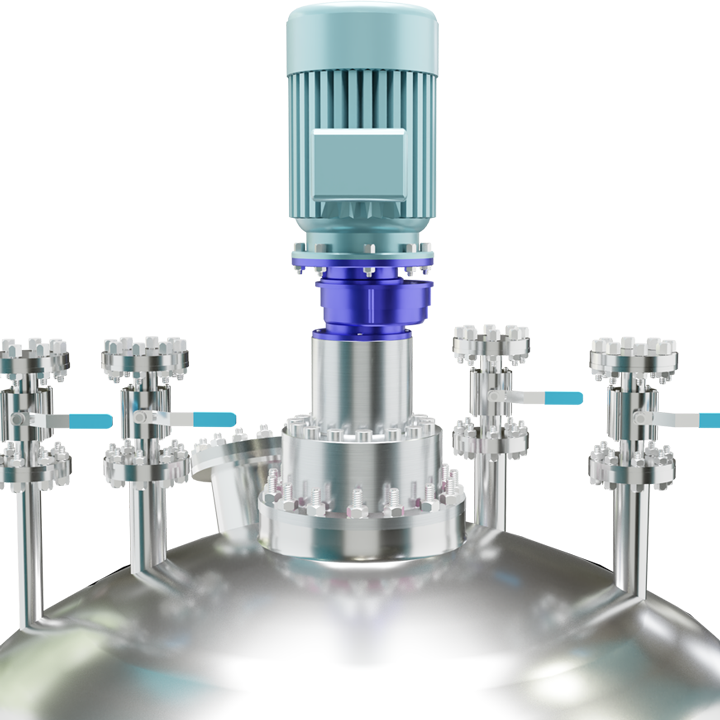

Omega-Kemix can supply Reactors with Top Entry Magnetic Seals. This sealing system comprehensively eliminates all possible leakage risks, by incorporating non-contact magnetic seals. The agitator shaft does not puncture the Reactor Vessel.

Catalogue